CNC Machined Parts Manufacturer in India Pune

ROBOCON CNC Pvt Ltd is a leading CNC machined parts manufacturer in India, delivering high-quality machining solutions for a wide range of industrial and engineering sectors. We specialize in producing precision machined parts and precision machined components that meet the strictest dimensional tolerances and functional requirements. Our advanced CNC turning and milling centers enable us to handle everything from one-off prototypes to full-scale production with consistent accuracy and finish.

In addition to production, we offer flexible and scalable contract CNC manufacturing parts services for global OEMs, automation solution providers, and high-performance industries. Every part we produce is custom-machined to customer drawings and specifications using top-grade materials, ensuring long-term reliability and performance. Partner with Robocon for your CNC machining needs in India and experience the benefits of quality, precision, and professional service.

CNC Machining for Emerging Sectors

-

Electric Vehicles (EVs) Precision machined parts for battery enclosures, motor housings, and heat sinks in next-gen EV platforms.

-

Electronics & PCB Enclosures Aluminum and plastic components for heat management and custom enclosures in high-performance electronics.

-

Space & Satellite Components Lightweight, high-strength parts for propulsion systems, payload brackets, and instruments used in space.

-

Robotics & Automation Precision brackets, gears, and end-effectors used in modern robotics and industrial automation systems.

-

Tooling & Die Making Custom molds, dies, jigs, and fixtures manufactured with tight tolerances and long-life materials.

-

Additive Manufacturing Support CNC-machined fixtures, post-processing tools, and precision inserts for hybrid and additive-subtractive manufacturing systems.

-

Lab & Scientific Equipment Precision parts for test rigs, spectrometry, microfluidics, and research-grade instrument assemblies.

-

Biotechnology & Diagnostics High-purity, chemically resistant components used in diagnostic equipment and bioprocessing systems.

-

Construction Equipment Durable, wear-resistant components for hydraulic systems and heavy machinery parts.

CNC Machining Services We Provide

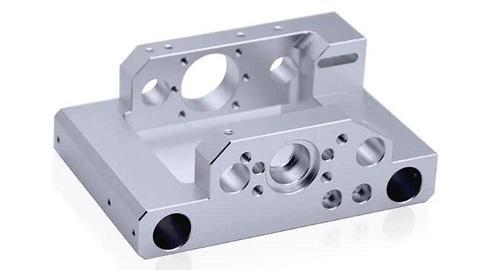

Precision Machined Components

Precision machined components are high-accuracy mechanical parts produced through controlled CNC machining processes. These components play a critical role in assemblies that demand tight tolerances, excellent repeatability, and long-term performance. Industries like medical devices, defense, oil and gas, and industrial automation heavily rely on these types of components for reliable functionality.

At ROBOCON CNC Pvt Ltd, we specialize in the manufacturing of precision machined components using advanced CNC milling and CNC turning technologies. Whether it's stainless steel (SS 304/316), aluminum, brass, or engineering plastics like Delrin, Nylon, or PTFE, we ensure high dimensional accuracy and surface finish as per customer drawings and 3D CAD models. Our team is skilled in handling complex geometries and can deliver fully machined parts ready for assembly or further treatment.

Every machined component goes through rigorous inspection processes, including CMM validation, surface finish checks, and dimensional control. We also support custom packaging, laser marking, and RoHS-compliant processes as per the customer’s requirement.

Precision Machined Parts & Precision Machining

Precision machined parts refer to custom CNC-turned or CNC-milled components that require extremely close tolerances and consistent finish. These parts are often designed for highly engineered applications in industries like semiconductor, automotive, robotics, and medical equipment. These can range from small intricate shafts to larger structural components.

Our precision machining services are optimized for both prototyping and batch production. Using 3-axis, 4-axis, and 5-axis CNC machines, we are able to produce highly complex components with micron-level accuracy. Our programming is done using advanced CAM software, ensuring efficient toolpaths, reduced cycle time, and best-in-class part quality.

ROBOCON CNC also provides services like thread milling, engraving, slotting, bore machining, and fine finishing using appropriate cutting tools and speeds. We maintain strict adherence to GD&T standards and ensure every machined part meets the exact functional and cosmetic requirements of the customer.

Contract CNC Manufacturing Parts

Contract CNC manufacturing refers to the long-term or project-based machining of parts as per buyer specifications. It involves a complete manufacturing solution — from raw material procurement and machining to finishing, quality control, and logistics. These projects often involve repeat production schedules and fixed lead times under a blanket PO or annual rate contract.

At ROBOCON CNC Pvt Ltd, we support OEMs and engineering companies through our contract CNC manufacturing services. We take full ownership of the production process, including raw material sourcing (with traceability certificates), fixture design, tool path optimization, in-process inspections, and final dispatch with documentation.

Our facility in Pune is equipped to handle large volumes of contract machined parts in various materials such as aluminum (6061, 7075), SS 304/316L, tool steel, and polymers. We follow lean manufacturing principles, ISO-compliant processes, and ERP-controlled scheduling to deliver parts consistently on time and within spec.

Industries We Serve

-

Automotive & EV

Automotive & EV

-

Medical & Diagnostics

Medical & Diagnostics

-

Metals & Mining

Metals & Mining

-

Oil & Gas -

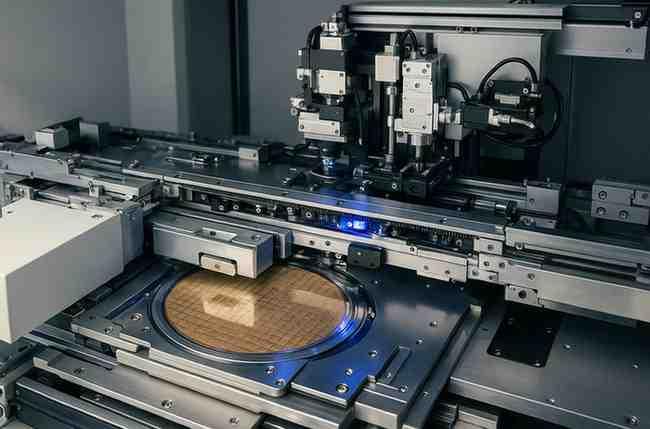

Semiconductor & Electronics -

Robotics & Automation

Robotics & Automation

Why Choose Robocon CNC?

- ISO-certified facility with state-of-the-art CNC machines

- Capability to machine aluminum, steel, titanium, and engineering plastics

- Dedicated team of skilled machinists and quality inspectors

- Strict quality control and adherence to tolerances up to ±0.005 mm

- Competitive pricing and prompt delivery schedules

When you choose Robocon, you’re partnering with a CNC machined parts manufacturer that prioritizes precision, quality, and customer satisfaction. We don’t just supply standard components — we tailor every solution to meet your unique requirements, whether it’s precision-machined parts or contract CNC manufacturing parts.

Since 2005, we’ve served global customers across diverse industries, delivering CNC turned and milled parts exactly when and how they’re needed. Our team takes pride in building long-term relationships and offering responsive support at every stage of the manufacturing process.

With Robocon, you can expect high-quality parts, rapid turnaround, and expert support from a company committed to excellence in CNC machining aluminum and other complex materials. Contact us today to discuss how we can help with your next project.

Modern CNC Machine Technology

CNC machines represent advanced manufacturing automation, utilizing computer-controlled systems for precise production. Key features include:

- Digital Control: Pre-programmed G-code commands manage speed, feed rate, and coordination

- Software Integration: CAD/CAM systems enable automated design-to-production workflow

- Expert Operation: Skilled machinists and programmers ensure optimal performance

This technology surpasses traditional manual machining, delivering superior precision and repeatability in manufacturing operations.

Impact of CNC Technology in Modern Manufacturing

CNC machining has revolutionized industrial production, enabling precision manufacturing of critical components across multiple sectors. The technology transforms traditional manufacturing into clean, efficient production environments with advanced automation and quality control.

- Applications: Industrial machinery, automotive components, medical devices

- Environment: Modern, automated facilities with precision equipment

- Quality: Enhanced accuracy and consistency in production

What is CNC Manufacturing?

CNC (Computerized Numerical Control) is an automated manufacturing process where pre-programmed software directs machine tools. Key aspects:

- Process: Computer-controlled cutting, shaping, and precision manufacturing

- Equipment: Advanced milling machines, lathes, and grinders

- Expertise: Combines mechanical design, technical drafting, and programming

- Materials: Precise machining of metals and plastics for industrial components

CNC Machining Career Opportunities

The CNC machining industry offers dynamic career paths in advanced manufacturing. CNC operators and machinists:

- Skills: Master design, programming, and precision manufacturing

- Scope: Manage complete production lifecycle from concept to finished product

- Growth: Join a rapidly expanding high-tech manufacturing sector

This career combines technical expertise with hands-on manufacturing, ideal for innovative professionals seeking rewarding opportunities in precision engineering.

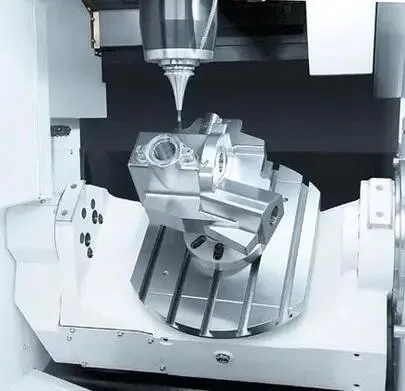

5-Axis CNC Machining and Its Advantages:

5-axis CNC machining involves the use of a computer-controlled machine with five axes of movement to manufacture precision machined components with exceptional complexity and accuracy. Unlike conventional 3-axis machines (X, Y, Z), 5-axis machines add two rotary axes (A and B), allowing the cutting tool to approach the workpiece from virtually any direction.

This advanced capability is essential for producing CNC turned and milled parts with complex geometries, curved surfaces, and features on multiple sides — all in a single setup. It reduces the need for multiple fixtures or manual repositioning, significantly improving machining efficiency and overall part quality.

5-axis CNC machining is especially valuable in high-precision industries such as aerospace, medical, and automotive manufacturing, where tight tolerances and superior surface finishes are mandatory. At Robocon, we leverage this technology to deliver consistent results, reduced lead times, and superior performance across our contract CNC manufacturing parts operations.

Machinability of different materials

Machinability of a material refers to its ability to be easily machined or shaped by various machining processes, such as cutting, drilling, milling, or turning. It is an important factor to consider when selecting a material for a particular machining application. Here you will find an overview of the machinability of common materials:

Steel Machining:

Steel is generally considered to have good machinability. However, the ease of machinability can vary depending on the type of steel and its specific properties. Carbon steels, in general, are easier to machine compared to high-alloy steels. The latter may necessitate the use of more specialized cutting tools and techniques.Aluminum Machining:

Aluminum is known for its excellent machinability.Compared to steel, it is a relatively soft material, allowing for higher cutting speeds and less tool wear. Our facility specializes in CNC machining aluminum components with high accuracy and efficiency.Copper Machining:

Copper is highly workable and similar to brass in machinability. It can be easily shaped and delivers excellent surface finishes, making it suitable for precision machined components. However, its high thermal conductivity often results in significant heat buildup during machining, which can impact tool life and accuracy. To achieve optimal results, copper machining requires careful heat management and the use of sharp cutting tools.Plastics Machining:

The machinability of plastics can vary greatly depending on the type of plastic. Certain plastics, like acrylic and nylon, are easy to work with and can be readily cut and shaped. On the other hand, plastics like high-density polyethylene (HDPE) can be more challenging to machine due to their tendency to deform or melt under the heat generated during the machining process.Stainless Steel Machining:

Stainless steel can vary in machinability depending on its composition and properties. Austenitic stainless steels such as 304 and 316 can be machined well, while duplex and precipitation hardening stainless steels can be more challenging due to their higher strength and toughness.Brass Machining:

Brass exhibits good to excellent machinability. Being a relatively soft material, it cuts easily and produces small chips. Thanks to this property, brass is renowned for its ability to create smooth surfaces, making it highly suitable for precision machining applications.Titanium Machining:

Titanium is a strong and lightweight metal widely used in aerospace, medical, and high-performance applications. However, it is relatively difficult to machine compared to other materials due to its tendency to work harden and generate excessive heat. This leads to increased tool wear and reduced cutting performance. Successful titanium machining requires specialized tooling, optimized cutting parameters, and advanced cooling techniques to maintain precision and extend tool life.Tool Steel Machining:

Tool steels are generally machinable, but the level of machinability can vary depending on the grade and hardness. Certain tool steels can be hardened to a high degree, necessitating the use of special machining techniques or processes, such as EDM (Electrical Discharge Machining).Precision CNC Machining Services for Every Industry

At Robocon CNC Pvt Ltd, we specialize in manufacturing high-precision CNC machined parts tailored to meet the demanding standards of industries like automotive, EV, medical devices, and oil & gas. Using advanced 3-axis to 5-axis CNC machining equipment and multi-axis turning centers, we deliver reliable solutions for prototypes and production batches. Our expertise covers a wide range of materials, including aluminum, stainless steel, and engineering plastics, ensuring versatility and quality at every step.

Whether you need cutting speed calculations for complex parts or fast online CNC quotations, Robocon CNC is your trusted partner for precision manufacturing in India. Get in touch today to discuss your project requirements and experience the difference in quality and service with Robocon CNC.

Get in Touch

If you are looking for a reliable CNC machined parts manufacturer in India, contact Robocon CNC Pvt Ltd today.