CNC Machining Service india pune

Welcome to Robocon - Precision CNC Manufacturing

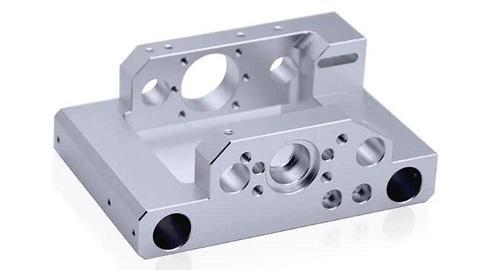

Established in Pune, Robocon is a premier CNC machining company delivering precision-engineered components across India and globally. Our advanced facility specializes in high-precision 3D and 2D parts manufacturing, utilizing cutting-edge CNC technology and expert craftsmanship.

Advanced CNC Technology: Our facility features state-of-the-art VMC (Vertical Machining Center) and HMC (Horizontal Machining Center) machines, enabling precision milling, turning, and complex component manufacturing.

High-Precision Manufacturing: We maintain industry-leading accuracy standards, ensuring each component meets exact specifications. Our expertise spans complex geometries, tight tolerances, and specialized materials.

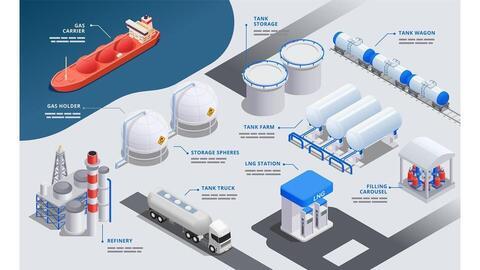

Quality Management System: ISO-certified quality processes and rigorous testing protocols guarantee flawless components. Our proven track record has earned trust across automotive, Oil & Gas, and medical industries.

Sectors we serve

Automotive

Medical

Metals & Mining

Oil & Gas

Semiconductor Industry

Renewable Energy

Advanced manufacturing for the pharmaceutical,semiconductor, oil & gas, and medical sectors

ROBOCON specializes in high-precision component manufacturing for pharmaceutical, semiconductor, oil & gas, and medical industries. Our validated manufacturing processes ensure:

- Ultra-Precise Tolerances: Meeting strict industry specifications with exceptional surface finish quality

- Validated Production: Rigorous quality controls for medical and pharmaceutical applications

- Complex Components: Manufacturing capability for intricate parts across all critical sectors

Our facility maintains ISO standards and industry-specific certifications, enabling us to deliver precision components that meet the most demanding specifications within our manufacturing capacity.

Understanding CNC Machining Technology

CNC (Computer Numerical Control) machining transforms digital designs into precision components through computer-controlled manufacturing. This automated process utilizes advanced machinery including:

- Multi-Axis Tools: Lathes, mills, routers, and grinders for complex 3D operations

- Digital Workflow: CAD designs converted to G-code for precise machine control

- Application Range: Serving automotive, aerospace, electronics, and prototyping needs

Our CNC capabilities deliver accuracy within 0.005mm tolerance, enabling consistently precise production across diverse industrial applications.

Modern CNC Machine Technology

CNC machines represent advanced manufacturing automation, utilizing computer-controlled systems for precise production. Key features include:

- Digital Control: Pre-programmed G-code commands manage speed, feed rate, and coordination

- Software Integration: CAD/CAM systems enable automated design-to-production workflow

- Expert Operation: Skilled machinists and programmers ensure optimal performance

This technology surpasses traditional manual machining, delivering superior precision and repeatability in manufacturing operations.

Impact of CNC Technology in Modern Manufacturing

CNC machining has revolutionized industrial production, enabling precision manufacturing of critical components across multiple sectors. The technology transforms traditional manufacturing into clean, efficient production environments with advanced automation and quality control.

- Applications: Industrial machinery, automotive components, medical devices

- Environment: Modern, automated facilities with precision equipment

- Quality: Enhanced accuracy and consistency in production

What is CNC Manufacturing?

CNC (Computerized Numerical Control) is an automated manufacturing process where pre-programmed software directs machine tools. Key aspects:

- Process: Computer-controlled cutting, shaping, and precision manufacturing

- Equipment: Advanced milling machines, lathes, and grinders

- Expertise: Combines mechanical design, technical drafting, and programming

- Materials: Precise machining of metals and plastics for industrial components

CNC Machining Career Opportunities

The CNC machining industry offers dynamic career paths in advanced manufacturing. CNC operators and machinists:

- Skills: Master design, programming, and precision manufacturing

- Scope: Manage complete production lifecycle from concept to finished product

- Growth: Join a rapidly expanding high-tech manufacturing sector

This career combines technical expertise with hands-on manufacturing, ideal for innovative professionals seeking rewarding opportunities in precision engineering.

Benefits and Advantages of CNC Machining Technology

Precision Manufacturing with CNC Machining

With an accuracy range of 0.005 mm, CNC machines achieve exceptional precision and eliminate human error. This degree of accuracy guarantees that manufactured parts adhere to exact specifications and tight tolerances. CNC machines can reliably create high-quality parts with little fluctuation because of computer-controlled automation.

High-Volume Production Capabilities

production">A CNC machine can repeat the machining process indefinitely once a part program is entered into it. Large volumes of parts can be produced consistently and effectively because to this capability. Scalability is a benefit of CNC machines; producers can easily adapt production volume to meet changing demands.

Advanced Manufacturing Capabilities

Components of any size, shape, or texture can be produced by CNC machines using CAD-CAM software. The capabilities of manual machines are surpassed by this potent mix of technologies, making it difficult, if not impossible, for even the most accomplished engineers to attain the same degree of intricacy and precision using traditional methods.

Consistent Product Quality

Every component made with CNC machinery adheres precisely to the requirements of the prototype. As a result, there is no longer a requirement for manual part inspection. The exact instructions of the part program, which contain the design parameters, are programmed into CNC machines. As a result, every product is guaranteed to fulfill the required dimensions and tolerances through a highly precise and reliable machining process.

Cost-Effective Manufacturing Solutions

There are several advantages to using CNC machines, including lower costs. The combination of high speed, efficiency, specialization and precision enables optimized production processes, less material waste and higher productivity. These factors ultimately contribute to cost savings and enable companies to offer competitive prices to their customers.

Enhanced Workplace Safety

In addition to the speedy production process and consistent performance, CNC machines also contribute to a safer working environment. Machining operations are performed in a closed environment, which helps increase safety. This enclosed design helps minimize potential hazards such as flying debris or accidental contact with moving parts, reducing the risk of accidents and ensuring a safer working environment for operators and others involved in the process.

Design and Program Retention

After loading a part program into a CNC machine, it can produce a perfect prototype based on the design. The program stores all the necessary information to accurately run the machine and replicate the object. This capability is facilitated by the master file, which ensures consistency and repeatability, even when external factors, such as a change of machine operator, come into play.

Minimal Maintenance Requirements

CNC machines do not usually require extensive maintenance. Regular maintenance includes tasks such as changing tools at appropriate intervals and performing light cleaning. These routine maintenance tasks can be accomplished without the need for professional service.

Versatile Manufacturing Capabilities

CNC machining is a versatile process that enables the production of complex and intricate components in various shapes. At ROBOCON CNC Pvt Ltd, we are proud to be the leading CNC machining provider in India.

5-axis Cnc Machining and its Advantages

5-axis Cnc machining is the use of a Cnc machine with five axes of motion to perform precision machining. Conventional Cnc machines typically have three axes (X, Y, and Z) that allow movement in three dimensions. however, 5-axis machines have two additional rotary axes (A and B) that allow for more complex and versatile machining. In 5-axis Cnc machining, the cutting tool can move in five different axes, allowing for greater flexibility and the production of more complicated and precise parts. This capability is especially useful for complex geometries, curved surfaces and multi-sided machining. The additional rotary axes allow the cutting tool to approach the part from different angles and orientations, reducing the need for multiple fixtures and improving overall accuracy. This capability is especially beneficial for industries such as aerospace, automotive and medical where complex components with tight tolerances are required. By using a 5-axis Cnc machine, manufacturers can achieve more efficient machining processes, reduce production time and improve the quality of finished parts. It enables the production of complex parts in a single setup, eliminating the need for multiple machines or manual repositioning of the workpiece. Overall, 5-axis Cnc machining offers advanced capabilities for manufacturing intricate and precise components, enabling greater design freedom and increased productivity in a variety of industries

Machinability of different materials

Machinability of a material refers to its ability to be easily machined or shaped by various machining processes, such as cutting, drilling, milling, or turning. It is an important factor to consider when selecting a material for a particular machining application. Here you will find an overview of the machinability of common materials:

- Steel Machining: Steel is generally considered to have good machinability. However, the ease of machinability can vary depending on the type of steel and its specific properties. Carbon steels, in general, are easier to machine compared to high-alloy steels. The latter may necessitate the use of more specialized cutting tools and techniques.

- Aluminum Machining: Aluminum is known for its excellent machinability. Compared to steel, it is a relatively soft material, allowing for higher cutting speeds and less tool wear. In addition, aluminum chips are easier to remove during machining.

- Copper Machining: Copper has good workability, similar to brass. It can be easily formed and offers good surface finishes. However, compared to other materials, copper has a higher thermal conductivity, which can lead to heat buildup during machining.

- Plastics Machining: The machinability of plastics can vary greatly depending on the type of plastic. Certain plastics, like acrylic and nylon, are easy to work with and can be readily cut and shaped. On the other hand, plastics like high-density polyethylene (HDPE) can be more challenging to machine due to their tendency to deform or melt under the heat generated during the machining process.

- Stainless Steel Machining: Stainless steel can vary in machinability depending on its composition and properties. Austenitic stainless steels such as 304 and 316 can be machined well, while duplex and precipitation hardening stainless steels can be more challenging due to their higher strength and toughness.

- Brass Machining:Brass exhibits good to excellent machinability. Being a relatively soft material, it cuts easily and produces small chips. Thanks to this property, brass is renowned for its ability to create smooth surfaces, making it highly suitable for precision machining applications.

- Titanium Machining: Titanium is relatively difficult to machine compared to other metals. It is a tough material that tends to work harden, resulting in tool wear and reduced cutting performance. Machining titanium, often requires special tools and techniques to overcome these challenges.

- Tool Steel Machining: Tool steels are generally machinable, but the level of machinability can vary depending on the grade and hardness. Certain tool steels can be hardened to a high degree, necessitating the use of special machining techniques or processes, such as EDM (Electrical Discharge Machining).

Why Robocon

When you choose to buy from Robocon, you are not simply purchasing items from a standardized list. Instead, we make it a point to understand your individual needs and tailor our product selection accordingly. This personal approach is at the core of our business. We value building relationships with all of our customers because every customer matters to us. At Robocon, we pride ourselves on serving companies from all over the world and providing them with the parts they need, exactly when they need them. Since 2005, our primary goal has been to deliver parts that meet our customers' exact specifications while minimizing lead time. Contact us today, and let us know how we can assist you!